Test Case AC6-07: Difference between revisions

David.Fowler (talk | contribs) mNo edit summary |

David.Fowler (talk | contribs) No edit summary |

||

| Line 1: | Line 1: | ||

{{AC|front=AC 6-07|description=AC 6-07 Description|testdata=AC 6-07 Test Data|cfdsimulations=AC 6-07 CFD Simulations|evaluation=AC 6-07 Evaluation|qualityreview=AC 6-07 Quality Review|bestpractice=AC 6-07 Best Practice Advice|relatedACs=AC 6-07 Related ACs}} | |||

='''Draft tube'''= | ='''Draft tube'''= | ||

| Line 740: | Line 741: | ||

Top Next | Top Next | ||

{{AC|front=AC 6-07|description=AC 6-07 Description|testdata=AC 6-07 Test Data|cfdsimulations=AC 6-07 CFD Simulations|evaluation=AC 6-07 Evaluation|qualityreview=AC 6-07 Quality Review|bestpractice=AC 6-07 Best Practice Advice|relatedACs=AC 6-07 Related ACs}} | |||

Revision as of 10:43, 10 March 2009

Draft tube

Application Challenge 6-07 © copyright ERCOFTAC 2004

Overview of Tests

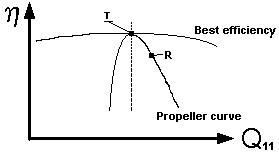

The data bank consists of data for two main cases. The first case is on-cam i.e. the top-point (T) on the propeller curve (single runner blade angle curve). The second case is off-cam i.e. the right-leg (R) on the propeller curve. Both are conducted at 60 % load, which is close to the best efficiency for the system, and at the same test head (H = 4.5 m).

The measurements were carried out during a period of five years. The model broke during this period and it was not possible to exactly repeat the same conditions after the accident. Therefore the data has been divided into before (r) and after (n), e.g. T(r) in the text (or Tr in file names) refers to the early Case T measurements. A more thorough discussion, that describes the different operational modes, can be found in Andersson (2003a). The (r)-measurements were used as initial conditions for both Turbine 99-workshops, while (n)-measurements are more complete with data at outlet section II and III.

The exact settings of the runner speed, N, and the resulting flow, Q, (i.e. PDPs) and the corresponding unit speeds, N11 and Q11 (i.e. GNDPs), are shown in Table EXP-A. In Figure 2.1 one can see an overview of the relation between the operational modes.

Figure 2.1. Sketch of the propeller curve and location of the test cases.

The flow of the draft tube has been studied with visualisations to get an overview of the main flow regimes. LDV has been used at a number of cross sections for velocity measurements. Wall pressure measurements has been performed to evaluate the performance of the draft tube. Figure 1.3 and 1.4 gives a description of the geometric location of each type of measurement. The available data has been listed in Table EXP-B.

In Andersson and Karlsson (1999) and Andersson (2003 a,b) a presentation of the methods used and a thorough discussion of the quality of the experimental data can be found.

|

NAME |

|

|

| |||||

|

|

|

|

|

|

|

|

| |

|

EXP 1a(T(r)-case) |

|

|

|

|

|

|

|

|

|

EXP 1b(T(n)-case) |

|

|

|

|

|

|

|

|

|

EXP 2a(R(r)-case) |

|

|

|

|

|

|

|

|

|

EXP 2b(R(n)-case) |

|

|

|

|

|

|

|

|

Table EXP-A Summary description of all test cases

Table EXP-B Summary description of all measured parameters and available data files

available data

unavailable data © ERCOFTAC 2004 Test case DATA © ERCOFTAC 2004 Description of Experiment

Case T and R are a collection of all experimental data, collected at each operational mode. The setting of GNDPs and PDPs can be found in Table EXP-A for each case. In section 1.4 a description of the geometric location of each type of measurement is given.

This paragraph is followed by a brief description of the available boundary conditions, a presentation of typical measurement errors at each section. After that follows a listing of available data files, first for Case T and second for Case R. © ERCOFTAC 2004 Boundary Data

The velocity measurements at section Ia serve as inlet conditions for the draft tube. These include the axial and the tangential mean and RMS velocity components. However, the radial velocity component is missing. More details can be found Gebart, Gustavsson and Karlsson (2000).

The model walls are painted steel surfaces and the surface roughness is estimated to be in the order of 10 mm, therefore the walls can be considered to be hydraulically smooth with the typical velocities in the experiment. Between model parts there can be discontinuities and weld seams that can cause local losses.

In Andersson (2003c) additional information e.g. about periodic behaviour at the inlet can be found. Also see section 3.2.3. regarding assumptions and settings used and recommended for CFD calculations. © ERCOFTAC 2004 Measurement Errors

In Andersson and Karlsson (1999) a thorough discussion of the quality of the experimental data can be found. Typical results from the evaluation can be seen in Table 1 and 2 (for case T). There is no major difference between case T and R. These are averaged values. The individual error estimation for each raw data value can be found in the supplied raw data files.

Table 2.1. The relative errors (%) in axial / tangential (or horizontal) mean velocity.

C.s. Ia

C.s. Ib

C.s. III

Random error

± 2.0 % / ± 3.5 %

± 2.0 % / ± 3.5 %

± 3.0 % / ± 5.0 %

Velocity bias

(axial component)

< +0.9 %

< + 1.4 %

< + 3.6 %

Probe volume location

± 1 % / ± 1-2 %

± 0.5 % /

± 0.5-5%

± 0.25 % /

± 0.25 %

Leakage

- 2 %

-

-

Symmetry

± 1 % / ± 1.25 %

± 2 % / ± 2.5 %

-

Total error

axial

tangential

x1 < ε < x2

- 4.1 % +1.3 %

- 5.2 % + 3.1 %

x1 < ε < x2

- 2.0 % + 4.3 %

>-5.9 % <+7.9 %

x1 < ε < x2

- 1.5 % + 6.6 %

- 3.5 % + 8.6 %

Table 2.2. Test of internal concistency (Q_int is the flow rate integrated from velocity measurements)

C.s. Ia *

C.s. Ib

C.s. III

Umean [m/s]

3.54

2.44

1.01

Vmean [m/s]

0.82

0.69

0.08

Q_int/Q [ ]

0.97

1.03

1.00

- mean values for the two measured cross sections

© ERCOFTAC 2004

Measured Data

The raw data files (*.dat, see below) are stored in ASCII-format. If nothing else is specified the format of the files used, is:

Header lines

position(x, y and z-coordinates) mean values rms values error margins

Velocity data is normalised with the mean value of the local average velocity (Q/Area of cross section) and pressure data is normalised with the dynamic pressure at the inlet and the pressure reference level is set to one at section IVb. The data has not been interpolated or otherwise manipulated if nothing else is stated.

In Andersson (1999, 2003a, 2003b) most of the data is presented and the main flow features discussed. (All contributions to Turbine 99-Workshop 2 are collected in the proceedings, Engström et al (2003)).

Exp 1a and 1b: Case T

Derived data:

DOAP:s calculated at available cross sections for case T(r).

DOAP.dat">TrDOAP.dat

DOAP:s calculated at available cross sections for case T(n).

DOAP.dat">TnDOAP.dat

Visualisations:

A number of pictures that describes the flow for Case T. The visualisations have focused on the streamlines close to the wall.

The pictures are stored in jpeg-format.

Figure 2.2. Streamlines close to the wall at the inlet cone.

A. Left view B. Top view

C. Right view D. Down stream view (c.s. III)

Figure 2.3. Streamlines close to the surface at the elbow and outlet diffuser.

Velocity and pressure measurements:

Section Ia

Figure 2.4. The normalised mean velocity components at profile Ia(1).

Normalised axial and tangential velocity measurements at cross section Ia, along profile 1 (-10°), for Case T(r). (See Figure 1.5).

TrIa1.dat

Normalised axial and tangential velocity measurements at cross section Ia, along profile 2 (180°), for Case T(r). (See Figure 1.5).

TrIa2.dat

Normalised axial and tangential velocity and pressure measurements at cross section Ia, along profile 1 (-10°), for Case T(n). (See Figure 1.5).

TnIa1.dat

Normalised static and dynamic pressure measurements at cross section Ia, along profile 3 ( -80°), for Case T(n). (See Figure 1.5).

TnIa3.dat

Normalised wall pressure measurements at cross section Ia, for Case T(n). (See Figure 1.5).

TnIaW.dat

Section Ib

Normalised axial and tangential velocity and pressure measurements at cross section Ib, along profile 1 (-80°), for Case T(r). (See Figure 1.5).

TrIb.dat

Normalised axial and tangential velocity and pressure measurements at cross section Ib, along profile 1 (-80°), for Case T(n). (See Figure 1.5).

TnIb.dat

Section II

Figure 2.5. The axial (contours) and horizontal (vectors) velocity components at c.s. II (down stream view).

Normalised axial and tangential velocity and pressure measurements at cross section II for Case T(n). (See Figure 1.4).

TnII.dat

Section III

Normalised axial and tangential velocity and pressure measurements at cross section III, for Case T(n). (See Figure 1.4).

TnIII.dat

Section IVb

Normalised wall pressure measurements at cross section IVb, for Case T(r). (See Figure 1.4).

TrIVb.dat

Centrelines

Normalised wall pressure measurements along the upper centre line, for Case T(n). (See Figure 1.7).

TnUcl.dat

Normalised wall pressure measurements along the lower centre line, for Case T(n). (See Figure 1.7).

TnLcl.dat

Exp 2a and 2b Case R

Derived data:

DOAP:s calculated at available cross sections for case R(r).

DOAP.dat">RrDOAP.dat

DOAP:s calculated at available cross sections for case R(n).

DOAP.dat">RnDOAP.dat

Visualisations:

A number of pictures that describes the flow for Case R. The visualisations have focused on the streamlines close to the wall.

The pictures are stored in jpeg-format.

Figure 2.6. Streamlines close to the wall at the inlet cone.

A. Left view B. Top view

C. Right view D. Down stream view (c.s. III)

Figure 2.7. Surface streamlines at the elbow and the first part of outlet diffuser.

Velocity and pressure measurements:

Section Ia

Figure 2.8. The normalised mean velocity components at profile Ia(1).

Normalised axial and tangential velocity measurements at cross section Ia, along profile 1 (-10°), for Case R(r). (See Figure 1.5).

RrIa1.dat

Normalised axial and tangential velocity measurements at cross section Ia, along profile 2 (180°), for Case R(r). (See Figure 1.5).

RrIa2.dat

Normalised axial and tangential velocity measurements at cross section Ia, along profile 1 (-10°), for Case R(n). (See Figure 1.5).

RnIa1.dat

Normalised static pressure measurements at cross section Ia, along profile 3 ( -80°), for Case R(n). (See Figure 1.5).

RnIa3.dat

Section Ib

Normalised axial and tangential velocity measurements at cross section Ib, along profile 1 (-80°), for Case R(r). (See Figure 1.5).

RrIb.dat

Normalised axial and tangential velocity measurements at cross section Ib, along profile 1 (-80°), for Case R(n). (See Figure 1.5).

RnIb.dat

Section II

Figure 2.9. The axial (contours) and horizontal (vectors) at c.s. II.

Normalised axial and tangential velocity and pressure measurements at cross section II for Case R(n). (See Figure 1.4).

RnII.dat

Section IVb

Normalised wall pressure measurements along at cross section IVb, for Case R(r). (See Figure 1.4).

RrIVb.dat

Centrelines

Normalised wall pressure measurements along the upper centre line, for Case R(n). (See Figure 1.7).

RnUcl.dat

Normalised wall pressure measurements along the lower centre line, for Case R(n). (See Figure 1.7).

RnLcl.dat © ERCOFTAC 2004 References

Andersson U. and R. Karlsson (1999) Quality aspects of the Turbine 99 draft tube experiments In: Proceedings from Turbine 99 – workshop on draft tube flow, Technical report, Luleå University of Technology, Sweden

Andersson U. (1999) Turbine 99 – Experiments On Draft Tube Flow (Test Case T) In: Proceedings from Turbine 99 – workshop on draft tube flow, Technical report, Luleå University of Technology, Sweden

Andersson U. (2000) An experimental study of the flow in a Sharp-Heel Draft Tube, Licentiate Thesis 2000:08, Luleå Unversity of Technology, Sweden

Andersson U. (2003a) Turbine 99 – Experiments On Draft Tube Flow (Test Case R) In: Proceedings from Turbine 99 – workshop 2 on draft tube flow.

Andersson U. (2003b) Test Case T – some new results and updates since Workshop I. In: Proceedings from Turbine 99 – workshop 2 on draft tube flow.

Andersson U. (2003c) Time resolved velocities at the inlet of the draft tube. To be submitted.

Gebart B.R., Gustavsson L.H. and Karlsson R.I. (editors) (2000) Proceedings of Turbine-99 – Workshop on draft tube flow in Porjus, Sweden, 20-23 June 1999, Technical report , 2000:11 from Luleå University of Technology, Luleå, Sweden. ISSN:1402-1536.

Engström, T.F., Gustavsson, L.H., & Karlsson, R.I. (2003), Proceedings of Turbine-99 - Workshop 2. The second ERCOFTAC Workshop on Draft Tube Flow. Älvkarleby, Sweden, June 18-20 2001. Available on the web, http://www.sirius.luth.se/strl/Turbine-99/index.htm.

In text called Proc.W2. © copyright ERCOFTAC 2004

Contributors: Rolf Karlsson - Vattenfall Utveckling AB

Site Design and Implementation: Atkins and UniS

Top Next