CFD Simulations AC2-08: Difference between revisions

| Line 7: | Line 7: | ||

====<span class="titlemark"> Introduction==== | ====<span class="titlemark"> Introduction==== | ||

The Tecflam configuration has been investigated by means of RANS (Reynolds Averaged Navier Stokes) and LES (Large Eddy Simulation). An overview will be presented in this section. Some details of the most recent work done by | The Tecflam configuration has been investigated by means of RANS (Reynolds Averaged Navier Stokes) and LES (Large Eddy Simulation). An overview will be presented in this section. Some details of the most recent work done by Kuenne et al.<ref name='kuenne_les_2011'>G. Kuenne, A. Ketelheun, J. Janicka, Combustion and Flame (2011) Accepted for publication.</ref> will be given. In order to avoid an overload of information the interested reader is referred to the cited references for a detailed discussion. | ||

====<span class="titlemark"> Overview of Simulations==== | ====<span class="titlemark"> Overview of Simulations==== | ||

Since measurements of temperature and species mass fractions exist only for the 30 kW configuration only this case has been investigated by means of numerical simulations. The studies are summarized in table | Since measurements of temperature and species mass fractions exist only for the 30 kW configuration only this case has been investigated by means of numerical simulations. The studies are summarized in table 4.1. | ||

<div class="table"> | <div class="table"> | ||

<div class="float"><div class="caption"><span class="id">Table 4.1: </span><span class="content">Summary of simulations done of the 30 kW case.</span></div><div class="tabular"> | |||

<div class="float"><div class="caption"><span class="id">Table | |||

{| id="TBL-3" class="tabular" rules="groups" rules="groups" | {| id="TBL-3" class="tabular" rules="groups" rules="groups" | ||

| | | | ||

---- | ---- | ||

| Line 26: | Line 24: | ||

| | | | ||

---- | ---- | ||

| | | | ||

---- | ---- | ||

| Line 35: | Line 32: | ||

|- id="TBL-3-1-" style="vertical-align: baseline" | |- id="TBL-3-1-" style="vertical-align: baseline" | ||

| id="TBL-3-1-1" class="td11" style="white-space: nowrap; text-align: center" | | | id="TBL-3-1-1" class="td11" style="white-space: nowrap; text-align: center" | | ||

| id="TBL-3-1-2" class="td11" style="white-space: nowrap; text-align: center" | Isothermal (30iso), CFD-Code / Publication | | id="TBL-3-1-2" class="td11" style="white-space: nowrap; text-align: center" | Isothermal (30iso), CFD-Code / Publication | ||

| id="TBL-3-1-3" class="td11" style="white-space: nowrap; text-align: center" | Reacting (PSF-30), CFD-Code / Publication | | id="TBL-3-1-3" class="td11" style="white-space: nowrap; text-align: center" | Reacting (PSF-30), CFD-Code / Publication | ||

|- class="hline" | |- class="hline" | ||

| | | | ||

| Line 47: | Line 44: | ||

| id="TBL-3-2-1" class="td11" style="white-space: nowrap; text-align: center" | RANS | | id="TBL-3-2-1" class="td11" style="white-space: nowrap; text-align: center" | RANS | ||

| id="TBL-3-2-2" class="td11" style="white-space: nowrap; text-align: center" | | | id="TBL-3-2-2" class="td11" style="white-space: nowrap; text-align: center" | | ||

FASTEST / | FASTEST / Hahn et al.<ref name='hahn_investigation_2008'>F. Hahn, C. Olbricht, C. Klewer, G. Kuenne, R. Ohnutek, J. Janicka, in: Proc. of the ISTP19 (2008d).</ref> | ||

| id="TBL-3-2-3" class="td11" style="white-space: nowrap; text-align: center" | | | id="TBL-3-2-3" class="td11" style="white-space: nowrap; text-align: center" | | ||

Ansys CFX / | Ansys CFX / Kuenne et al.<ref name='kuenne_hybrid_2009'>G. Kuenne, C. Klewer, J. Janicka, ASME Turbo Expo Conference Proceedings (2009) 369–381.</ref> | ||

|- class="hline" | |- class="hline" | ||

| | | | ||

| Line 60: | Line 57: | ||

| id="TBL-3-3-1" class="td11" style="white-space: nowrap; text-align: center" | LES | | id="TBL-3-3-1" class="td11" style="white-space: nowrap; text-align: center" | LES | ||

| id="TBL-3-3-2" class="td11" style="white-space: nowrap; text-align: center" | | | id="TBL-3-3-2" class="td11" style="white-space: nowrap; text-align: center" | | ||

FASTEST / | FASTEST / Hahn et al.<ref name='hahn_investigation_2008'> </ref> | ||

| id="TBL-3-3-3" class="td11" style="white-space: nowrap; text-align: center" | | | id="TBL-3-3-3" class="td11" style="white-space: nowrap; text-align: center" | | ||

FASTEST / | FASTEST / Kuenne et al.<ref name='kuenne_les_2011'> </ref> | ||

|- id="TBL-3-4-" style="vertical-align: baseline" | |- id="TBL-3-4-" style="vertical-align: baseline" | ||

| id="TBL-3-4-1" class="td11" style="white-space: nowrap; text-align: center" | | | id="TBL-3-4-1" class="td11" style="white-space: nowrap; text-align: center" | | ||

| id="TBL-3-4-2" class="td11" style="white-space: nowrap; text-align: center" | | | id="TBL-3-4-2" class="td11" style="white-space: nowrap; text-align: center" | | ||

FASTEST / | FASTEST / Kuenne et al.<ref name='kuenne_les_2011'> </ref> | ||

| id="TBL-3-4-3" class="td11" style="white-space: nowrap; text-align: center" | | | id="TBL-3-4-3" class="td11" style="white-space: nowrap; text-align: center" | | ||

|- class="hline" | |- class="hline" | ||

| Line 80: | Line 77: | ||

</div></div> | </div></div> | ||

</div> | </div> | ||

====<span class="titlemark"> CFD Code==== | ====<span class="titlemark"> CFD Code==== | ||

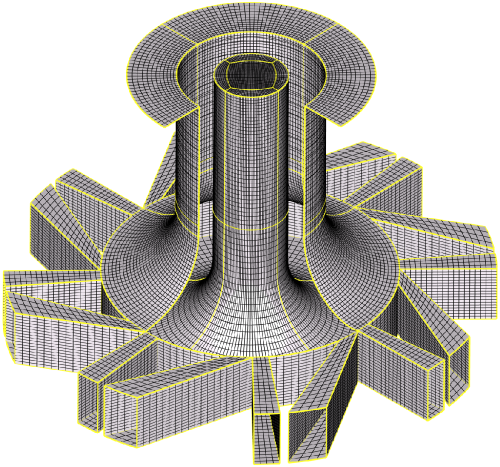

The three-dimensional finite volume code FASTEST uses block-structured, hexahedral, boundary fitted grids to represent complex geometries. Regarding the velocity, spatial discretization is based on multi-dimensional Taylor series expansion | The three-dimensional finite volume code FASTEST uses block-structured, hexahedral, boundary fitted grids to represent complex geometries. Regarding the velocity, spatial discretization is based on multi-dimensional Taylor series expansion<ref name='lehnhaeuser_improved_2002'>T. Lehnhaeuser, M. Schaefer, International Journal for Numerical Methods in Fluids 38 (2002) 625–645.</ref> to ensure second order accuracy on arbitrary grids. To assure boundedness of scalar quantities the TVD-limiter suggested by Zhou et al.<ref name='zhou_transonic_1995'>G. Zhou, L. Davidson, E. Olsson, in: Fourteenth International Conference on Numerical Methods in Fluid Dynamics, 1995, pp. 372–378.</ref> is used. An explicit Runge-Kutta scheme is used for the time advancement of momentum and species mass fractions with temperature dependent transport coefficients. The code solves the incompressible, variable density, Navier-Stokes equations where an equation for the pressure correction is solved within each Runge-Kutta stage to satisfy continuity. The solver is based on an ILU matrix decomposition and uses the strongly implicit procedure<ref name='stone_iterative_1968'>H.L. Stone, SIAM Journal on Numerical Analysis 5 (1968) 530–558.</ref> to take advantage of the block-structure. | ||

====<span class="titlemark"> Computational Domain, Spatial Discretization and Boundary Conditions==== | ====<span class="titlemark"> Computational Domain, Spatial Discretization and Boundary Conditions==== | ||

| Line 99: | Line 96: | ||

====<span class="titlemark"> Physical Modeling==== | ====<span class="titlemark"> Physical Modeling==== | ||

The turbulent flowfield is approximated by means of LES (Large Eddy Simulation). Sub grid fluxes of momentum are accounted for by the eddy viscosity approach proposed by | The turbulent flowfield is approximated by means of LES (Large Eddy Simulation). Sub grid fluxes of momentum are accounted for by the eddy viscosity approach proposed by Smagorinsky <ref name='smagorinsky_general_1963'>J. Smagorinsky, Monthly Weather Rev. 91 (1963) 99–164.</ref> where the model coefficient is obtained by the dynamic procedure of Germano et al.<ref name='germano_dynamic_1991'>M. Germano, U. Piomelli, P. Moin, W.H. Cabot, Physics of Fluids A: Fluid Dynamics 3 (1991) 1760–1765.</ref> with a modification by Lilly<ref name='lilly_proposed_1992'>D.K. Lilly, Physics of Fluids A: Fluid Dynamics 4 (1992) 633–635.</ref>. Outside of the reaction zone a gradient approach has been chosen for the sub grid flux of scalar quantities with a turbulent Schmidt number of 0.7. | ||

The method to treat the chemical reaction is based on a thickened flame approach | The method to treat the chemical reaction is based on a thickened flame approach <ref name='butler_numerical_1977'>T. Butler, P. O’Rourke, Symposium (International) on Combustion 16 (1977) 1503–1515.</ref><ref name='orourke_two_1979'>P.J. O’Rourke, F.V. Bracco, Journal of Computational Physics 33 (1979) 185–203.</ref><ref name='angelberger_large_1998'>C. Angelberger, D. Veynante, F. Egolfopoulos, T. Poinsot, in: Proceedings of the Summer Program 1998, Center for Turbulence Research, pp. 61–82.</ref><ref name='colin_thickened_2000'>O. Colin, F. Ducros, D. Veynante, T. Poinsot, Physics of Fluids 12 (2000) 1843–1863.</ref> <ref name='charlette_power-law_2002'>F. Charlette, C. Meneveau, D. Veynante, Combustion and Flame 131 (2002) 159–180.</ref> coupled to FGM (flamelet generated manifolds,<ref name='van_oijen_modelling_2000'> J.A. van Oijen, L.P.H. de Goey, Combustion Science and Technology 161 (2000) 113–137.</ref> <ref name='van_oijen_modeling_2001'>J.A. van Oijen, F.A. Lammers, L.P.H. de Goey, Combustion and Flame 127 (2001) 2124–2134.</ref> tabulated chemistry using the mixture fraction and a reaction progress variable. Details about the method and its verification can be found in Kuenne et al.<ref name='kuenne_les_2011'> </ref>. | ||

Revision as of 14:29, 11 January 2011

Premixed Methane-Air Swirl Burner (TECFLAM)

Application Challenge 2-08 © copyright ERCOFTAC 2011

Introduction

The Tecflam configuration has been investigated by means of RANS (Reynolds Averaged Navier Stokes) and LES (Large Eddy Simulation). An overview will be presented in this section. Some details of the most recent work done by Kuenne et al.[1] will be given. In order to avoid an overload of information the interested reader is referred to the cited references for a detailed discussion.

Overview of Simulations

Since measurements of temperature and species mass fractions exist only for the 30 kW configuration only this case has been investigated by means of numerical simulations. The studies are summarized in table 4.1.

CFD Code

The three-dimensional finite volume code FASTEST uses block-structured, hexahedral, boundary fitted grids to represent complex geometries. Regarding the velocity, spatial discretization is based on multi-dimensional Taylor series expansion[4] to ensure second order accuracy on arbitrary grids. To assure boundedness of scalar quantities the TVD-limiter suggested by Zhou et al.[5] is used. An explicit Runge-Kutta scheme is used for the time advancement of momentum and species mass fractions with temperature dependent transport coefficients. The code solves the incompressible, variable density, Navier-Stokes equations where an equation for the pressure correction is solved within each Runge-Kutta stage to satisfy continuity. The solver is based on an ILU matrix decomposition and uses the strongly implicit procedure[6] to take advantage of the block-structure.

Computational Domain, Spatial Discretization and Boundary Conditions

As illustrated in Fig. 4.1 and 4.2 the computational domain starts after the plenum chamber at the inlets of the tangential and radial channels. Here the mass flow given by the measurements has been set. No additional velocity fluctuation is forced here since the inclusion of the geometry upstream of the nozzle exit has been found to be sufficient to allow the turbulent structures to form. The equivalence ratio has been set to ϕ = 0.83 at the inlet since the methane-air mixture has been verified by the measurements to be mixed homogeneously. The diameter of the computational domain matches the extend of the coflowing air issuing with 0.5m/s. The boundaries in radial and axial direction have been found to be sufficiently far away from the region of interest (i.e. the swirler exit region). The block structured grid contains 3.2 million control volumes and has been elliptically smoothed to obtain a better orthogonality. The grid has been refined towards the near nozzle region whereas it gets coarser with increasing distance to spare cells.

Physical Modeling

The turbulent flowfield is approximated by means of LES (Large Eddy Simulation). Sub grid fluxes of momentum are accounted for by the eddy viscosity approach proposed by Smagorinsky [7] where the model coefficient is obtained by the dynamic procedure of Germano et al.[8] with a modification by Lilly[9]. Outside of the reaction zone a gradient approach has been chosen for the sub grid flux of scalar quantities with a turbulent Schmidt number of 0.7.

The method to treat the chemical reaction is based on a thickened flame approach [10][11][12][13] [14] coupled to FGM (flamelet generated manifolds,[15] [16] tabulated chemistry using the mixture fraction and a reaction progress variable. Details about the method and its verification can be found in Kuenne et al.[1].

Contributors: Johannes Janicka (EKT), Guido Kuenne (EKT), Andreas Dreizler (RSM)

- ↑ 1.0 1.1 1.2 1.3 G. Kuenne, A. Ketelheun, J. Janicka, Combustion and Flame (2011) Accepted for publication.

- ↑ 2.0 2.1 F. Hahn, C. Olbricht, C. Klewer, G. Kuenne, R. Ohnutek, J. Janicka, in: Proc. of the ISTP19 (2008d).

- ↑ G. Kuenne, C. Klewer, J. Janicka, ASME Turbo Expo Conference Proceedings (2009) 369–381.

- ↑ T. Lehnhaeuser, M. Schaefer, International Journal for Numerical Methods in Fluids 38 (2002) 625–645.

- ↑ G. Zhou, L. Davidson, E. Olsson, in: Fourteenth International Conference on Numerical Methods in Fluid Dynamics, 1995, pp. 372–378.

- ↑ H.L. Stone, SIAM Journal on Numerical Analysis 5 (1968) 530–558.

- ↑ J. Smagorinsky, Monthly Weather Rev. 91 (1963) 99–164.

- ↑ M. Germano, U. Piomelli, P. Moin, W.H. Cabot, Physics of Fluids A: Fluid Dynamics 3 (1991) 1760–1765.

- ↑ D.K. Lilly, Physics of Fluids A: Fluid Dynamics 4 (1992) 633–635.

- ↑ T. Butler, P. O’Rourke, Symposium (International) on Combustion 16 (1977) 1503–1515.

- ↑ P.J. O’Rourke, F.V. Bracco, Journal of Computational Physics 33 (1979) 185–203.

- ↑ C. Angelberger, D. Veynante, F. Egolfopoulos, T. Poinsot, in: Proceedings of the Summer Program 1998, Center for Turbulence Research, pp. 61–82.

- ↑ O. Colin, F. Ducros, D. Veynante, T. Poinsot, Physics of Fluids 12 (2000) 1843–1863.

- ↑ F. Charlette, C. Meneveau, D. Veynante, Combustion and Flame 131 (2002) 159–180.

- ↑ J.A. van Oijen, L.P.H. de Goey, Combustion Science and Technology 161 (2000) 113–137.

- ↑ J.A. van Oijen, F.A. Lammers, L.P.H. de Goey, Combustion and Flame 127 (2001) 2124–2134.