DNS 1-3 Description: Difference between revisions

| Line 25: | Line 25: | ||

|} | |} | ||

For the current diffuser, the upper-wall expansion angle is 11.3° and the side-wall expansion angle is 2.56°. The flow in the inlet duct (height h=1, width B=3.33) corresponds to fully-developed turbulent square duct flow. The <math>L=15h</math> long diffuser section is followed by a straight outlet part (12.5h long). Downstream of this the flow goes through a 10h long contraction ending with a 5h duct in order to minimize the effect of the outlet to the diffuser. A difference from the DNS performed by Ohlsson ''et al.'' (2010) is that the present geometry does not have any curvature radius on the walls transitioning between diffuser and the straight duct parts. The geometry also includes a long inlet duct of 55h long in order to allow the flow in the inlet duct to fully develop. Before this, there is a section of 5h long with a small chevron at 3h from the inlet for 0.1h in order to trigger the turbulent transition on the square duct. An overview of the computational geometry with details on the square duct is shown on [[ | For the current diffuser, the upper-wall expansion angle is 11.3° and the side-wall expansion angle is 2.56°. The flow in the inlet duct (height h=1, width B=3.33) corresponds to fully-developed turbulent square duct flow. The <math>L=15h</math> long diffuser section is followed by a straight outlet part (12.5h long). Downstream of this the flow goes through a 10h long contraction ending with a 5h duct in order to minimize the effect of the outlet to the diffuser. A difference from the DNS performed by Ohlsson ''et al.'' (2010) is that the present geometry does not have any curvature radius on the walls transitioning between diffuser and the straight duct parts. The geometry also includes a long inlet duct of 55h long in order to allow the flow in the inlet duct to fully develop. Before this, there is a section of 5h long with a small chevron at 3h from the inlet for 0.1h in order to trigger the turbulent transition on the square duct. An overview of the computational geometry with details on the square duct is shown on [[lib:DNS_1-3_description_#figure2|Fig. 2]]. | ||

<div id="figure2"></div> | <div id="figure2"></div> | ||

Revision as of 11:03, 16 November 2021

Introduction

The 3D (Stanford) Diffuser is a well documented case with complex internal corner flow and 3D separation while having a relatively simple geometry. It has an inlet section, an expansion section and an outlet section (see Figure 1). The flow at the inlet is assumed to be a fully developed rectangular channel flow. At the outlet, standard Dirichlet condition for the pressure is prescribed. An inflow Reynolds number of 10000 is considered based on the duct height and the flow is considered to be incompressible. The following DNS data has been obtained using the in-house Finite Element Method (FEM) code Alya developed at BSC.

Review of previous studies

This diffuser configuration has already been investigated in the framework of two ERCOFTAC-SIG15 Workshops and in the European ATAAC project. They studied both 3D diffuser configurations (denoted as SIG15 Case 13.2-1 and SIG15 Case 13.2-2, respectively) and were held in Austria (September, 2008) and Italy (September, 2009). Both in the workshops and in the ATAAC project a wide range of turbulence models in both LES and RANS frameworks as well as some novel Hybrid LES/RANS formulations have been employed. The corresponding reports are published in the ERCOFTAC Bulletin Issues, see Steiner et al. (2009), Jakirlić et al. (2010b) and references within UFR4-16. A list of all computational contributions to the workshops with some basic information about the methods and models used and corresponding grid resolution is given in the UFR4-16 case.

The only high-fidelity data available is the DNS performed by Ohlsson et al. (2010). As with the present case, this DNS had a Re=10000 and was solved using a spectral element code with 11th order polynomials. Their calculations were performed on the Blue Gene/P at ALCF, using 32768 cores and 8 million core hours. Another computation was performed on the cluster “Ekman” at PDC, Stockholm, Sweden, using 2048 cores and a total of 4 million core hours. The flow was computed for 13 flow-through-times (based on the bulk inlet velocity and diffuser length) before gathering statistics, which were gathered over an additional 21 flowthrough-times.

Description of the test case

The diffuser studied is the UFR4-16 Test Case, diffuser 1, provided in the ERCOFTAC database.

Geometry and flow parameters

The diffuser shape, dimensions and the coordinate system are shown in Fig. 1 (reproduced from UFR4-16 Test Case).

|

| Figure 1: Geometry of the 3-D diffuser 1 considered (not to scale), Cherry et al. (2008); see also Jakirlić et al. (2010a). |

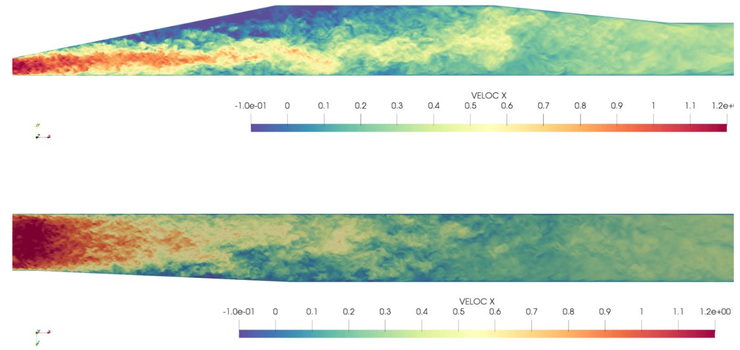

For the current diffuser, the upper-wall expansion angle is 11.3° and the side-wall expansion angle is 2.56°. The flow in the inlet duct (height h=1, width B=3.33) corresponds to fully-developed turbulent square duct flow. The long diffuser section is followed by a straight outlet part (12.5h long). Downstream of this the flow goes through a 10h long contraction ending with a 5h duct in order to minimize the effect of the outlet to the diffuser. A difference from the DNS performed by Ohlsson et al. (2010) is that the present geometry does not have any curvature radius on the walls transitioning between diffuser and the straight duct parts. The geometry also includes a long inlet duct of 55h long in order to allow the flow in the inlet duct to fully develop. Before this, there is a section of 5h long with a small chevron at 3h from the inlet for 0.1h in order to trigger the turbulent transition on the square duct. An overview of the computational geometry with details on the square duct is shown on Fig. 2.

|

| Figure 2: Detail of the computational domain used for this test case. |

The bulk velocity in the inflow duct is in the x-direction resulting in the Reynolds number based on the inlet channel height of 10000.

Boundary conditions

The inflow is set to . Turbulence is triggered by creating a small discontinuity in the form of a small chevron in the channel. The exit is set to while the walls of the channel and the diffuser are set to no slip.

References

- Ohlsson, J., Schlatter, P., Fischer P.F. and Henningson, D.S. (2009): DNS of three-dimensional separation in turbulent diffuser flows. In Advances in Turbulence XII, Proceedings of the 12th EUROMECH European Turbulence Conference, Marburg. Springer Proceedings in Physics, Vol. 132, ISBN 978-3-642-03084-0

- Ohlsson, J., Schlatter, P., Fischer P.F. and Henningson, D.S. (2010): DNS of separated flow in a three-dimensional diffuser by the spectral-element method. J. Fluid Mech., Vol. 650, pp. 307–318

- Steiner, H., Jakirlić, S., Kadavelil, G., Šarić, S., Manceau, R. and Brenn. G. (2009): Report on 13th ERCOFTAC Workshop on Refined Turbulence Modelling. September 25–26, 2008, Graz University of Technology, ERCOFTAC Bulletin, No. 79, pp. 24–29

- Jakirlić, S., Kadavelil, G., Sirbubalo, E., von Terzi, D., Breuer, M. and Borello, D. (2010b): 14th ERCOFTAC SIG15 Workshop on Turbulence Modelling: Turbulent Flow Separation in a 3-D Diffuser. "Sapienza" University of Rome, September 18, 2009, ERCOFTAC Bulletin, December Issue, No. 85, pp. 5–13

Contributed by: Oriol Lehmkuhl, Arnau Miro — Barcelona Supercomputing Center (BSC)

© copyright ERCOFTAC 2024