Abstr:Premixed Methane-Air Swirl Burner (TECFLAM): Difference between revisions

Joe.Morris (talk | contribs) m (Removed semantic markup.) Tag: Manual revert |

|||

| (5 intermediate revisions by 3 users not shown) | |||

| Line 14: | Line 14: | ||

== Abstract == | == Abstract == | ||

The TECFLAM configuration is a lean premixed methane-air burner with a high swirl intensity where the flame is stabilized by the recirculation of hot products. | The TECFLAM configuration is a lean premixed methane-air burner with a high swirl intensity where the flame is stabilized by the recirculation of hot products. The test case presented here is a further development of the configurations defined within the TECFLAM (TEChnical FLAMes) project founded in 1984. Back then a co-operation between several German research institutions aimed to define burners to improve the understanding of combustion processes and to obtain validation data for simulations (see also AC2-06). | ||

The burner has been designed to investigate essential features found in industrial lean premixed combustors. An extensive set of measurements obtained by advanced laser-diagnostics exists to: | |||

* Give insight into the underlying physics to gain a deeper understanding of the relevant phenomena | * Give insight into the underlying physics to gain a deeper understanding of the relevant phenomena | ||

* Build a database well suited for CFD validation | * Build a database well suited for CFD validation | ||

Validation data is available for the reacting and non-reacting cases using the same velocity boundary conditions to allow for a separate assessment of the applied turbulence model and combustion model. A total of four cases are considered in this AC consisting of a 30 kW and 150 kW flame and their corresponding isothermal cases. | Validation data is available for the reacting and non-reacting cases using the same velocity boundary conditions to allow for a separate assessment of the applied turbulence model and combustion model. A total of four cases are considered in this AC consisting of a 30 kW and 150 kW flame and their corresponding isothermal cases. The database for validation contains measurements of velocities, species mass fractions, temperature as well as integral length scales and the frequency spectrum at the nozzle exit. Simulation results obtained from RANS (Reynolds Averaged Navier Stokes) and LES (Large Eddy Simulation) investigations will be presented and compared with the experimental results. | ||

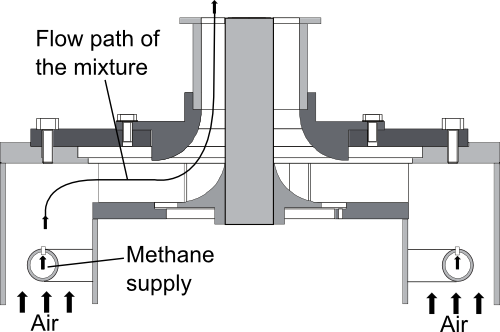

[[Image:nozzle_only.png|left|frame|The Tecflam swirl burner. 2-D cut of the experimental setup.]] | [[Image:nozzle_only.png|left|frame|The Tecflam swirl burner. 2-D cut of the experimental setup.]] | ||

Latest revision as of 11:35, 14 January 2022

Application Area 2: Combustion

Application Challenge AC2-08

Abstract

The TECFLAM configuration is a lean premixed methane-air burner with a high swirl intensity where the flame is stabilized by the recirculation of hot products. The test case presented here is a further development of the configurations defined within the TECFLAM (TEChnical FLAMes) project founded in 1984. Back then a co-operation between several German research institutions aimed to define burners to improve the understanding of combustion processes and to obtain validation data for simulations (see also AC2-06). The burner has been designed to investigate essential features found in industrial lean premixed combustors. An extensive set of measurements obtained by advanced laser-diagnostics exists to:

- Give insight into the underlying physics to gain a deeper understanding of the relevant phenomena

- Build a database well suited for CFD validation

Validation data is available for the reacting and non-reacting cases using the same velocity boundary conditions to allow for a separate assessment of the applied turbulence model and combustion model. A total of four cases are considered in this AC consisting of a 30 kW and 150 kW flame and their corresponding isothermal cases. The database for validation contains measurements of velocities, species mass fractions, temperature as well as integral length scales and the frequency spectrum at the nozzle exit. Simulation results obtained from RANS (Reynolds Averaged Navier Stokes) and LES (Large Eddy Simulation) investigations will be presented and compared with the experimental results.

Contributors: Guido Kuenne (EKT), Andreas Dreizler (RSM), Johannes Janicka (EKT)

EKT: Institute of Energy and Power Plant Technology, Darmstadt University of Technology

RSM: Institute Reactive Flows and Diagnostics, Center of Smart Interfaces, Darmstadt University of Technology

© copyright ERCOFTAC 2011